The Complete Guide to Custom Mechanical Parts Design

Understanding Custom Mechanical Parts Design

Custom mechanical parts design is a crucial aspect of engineering and manufacturing that allows for the creation of components tailored to specific applications. This process involves creating parts that meet unique requirements, which standard components cannot fulfill. By understanding the fundamentals of custom design, businesses can enhance their products' performance and efficiency.

The Design Process

Initial Conceptualization

The design process begins with a clear understanding of the project's requirements. This involves identifying the part's function, material specifications, and any constraints. Collaboration between engineers and clients is essential at this stage to ensure all needs are addressed.

Prototyping and Testing

Once the initial design is complete, prototyping is the next step. Prototypes allow designers to test the part's functionality and make necessary adjustments. This stage is vital for identifying potential issues and ensuring the part performs as expected.

Materials and Manufacturing Techniques

Material Selection

Choosing the right material is critical in custom mechanical parts design. Factors such as strength, weight, and cost must be considered. Common materials include metals, plastics, and composites, each offering unique advantages and limitations.

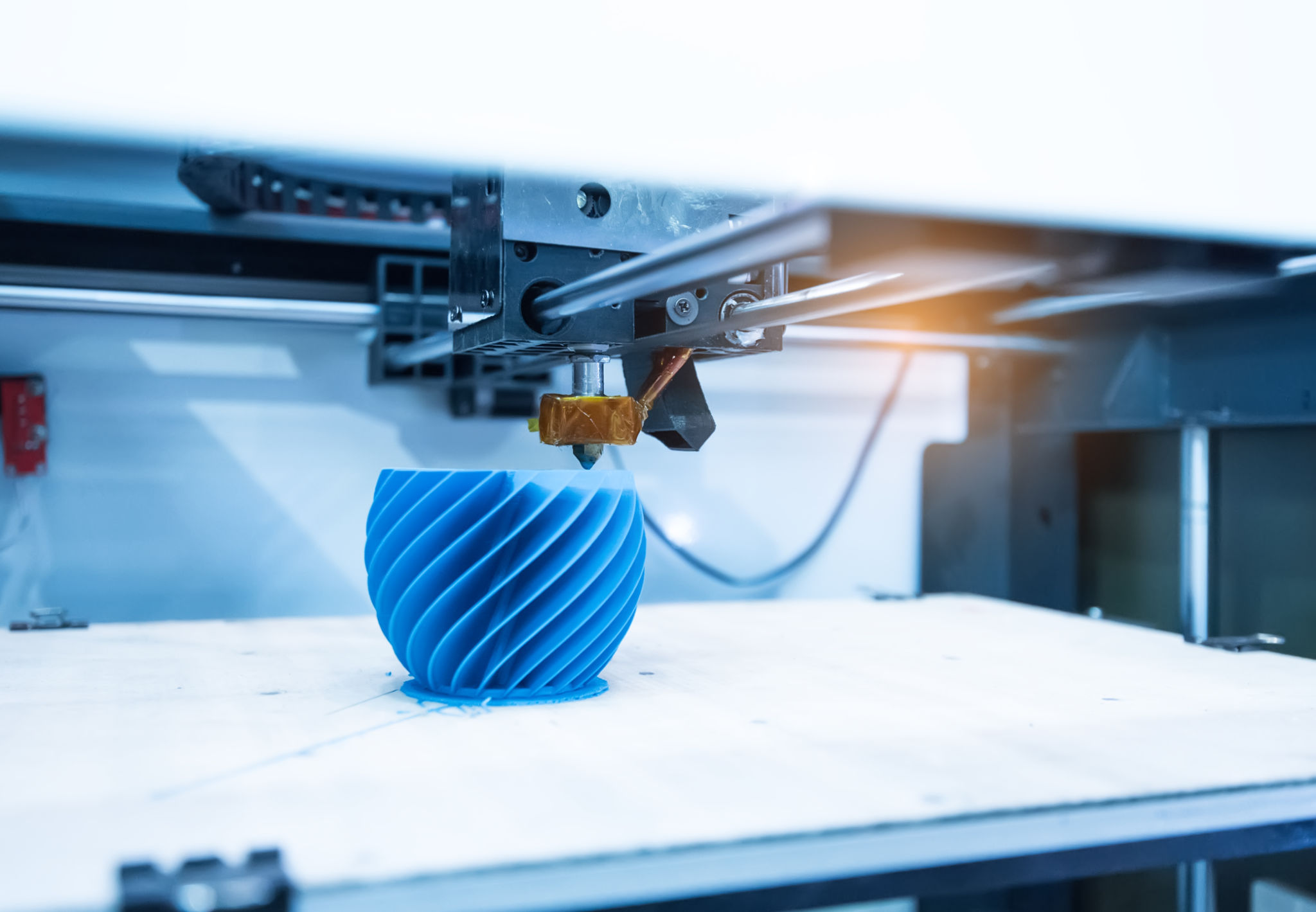

Advanced Manufacturing Techniques

Advanced techniques like CNC machining and 3D printing have revolutionized custom part manufacturing. These methods offer precision and flexibility, enabling the creation of complex geometries and reducing lead times.

Benefits of Custom Mechanical Parts

Custom parts offer numerous advantages, including improved performance, enhanced durability, and reduced maintenance costs. By tailoring components to specific applications, businesses can achieve optimal efficiency and longevity.

Cost Considerations

While custom parts can be more expensive upfront, they often lead to cost savings in the long run. Reduced downtime, better performance, and fewer replacements contribute to a lower total cost of ownership.

Implementing Custom Designs

Successfully implementing custom mechanical parts requires a strategic approach. Collaboration with experienced designers and manufacturers ensures that the parts meet all necessary specifications and deliver the desired results.

Future Trends

The future of custom mechanical parts design is promising, with advancements in technology continually expanding possibilities. Innovations in materials and manufacturing processes are likely to further enhance the capabilities and applications of custom parts.