The Future of Custom Mechanical Parts Design: Trends and Innovations

Introduction to Custom Mechanical Parts Design

The landscape of custom mechanical parts design is rapidly evolving, driven by technological advancements and a growing demand for enhanced precision and efficiency. From 3D printing to advanced CAD software, the industry is embracing new tools and methodologies to meet the ever-changing needs of engineers and manufacturers. In this blog post, we'll explore the latest trends and innovations that are shaping the future of custom mechanical parts design.

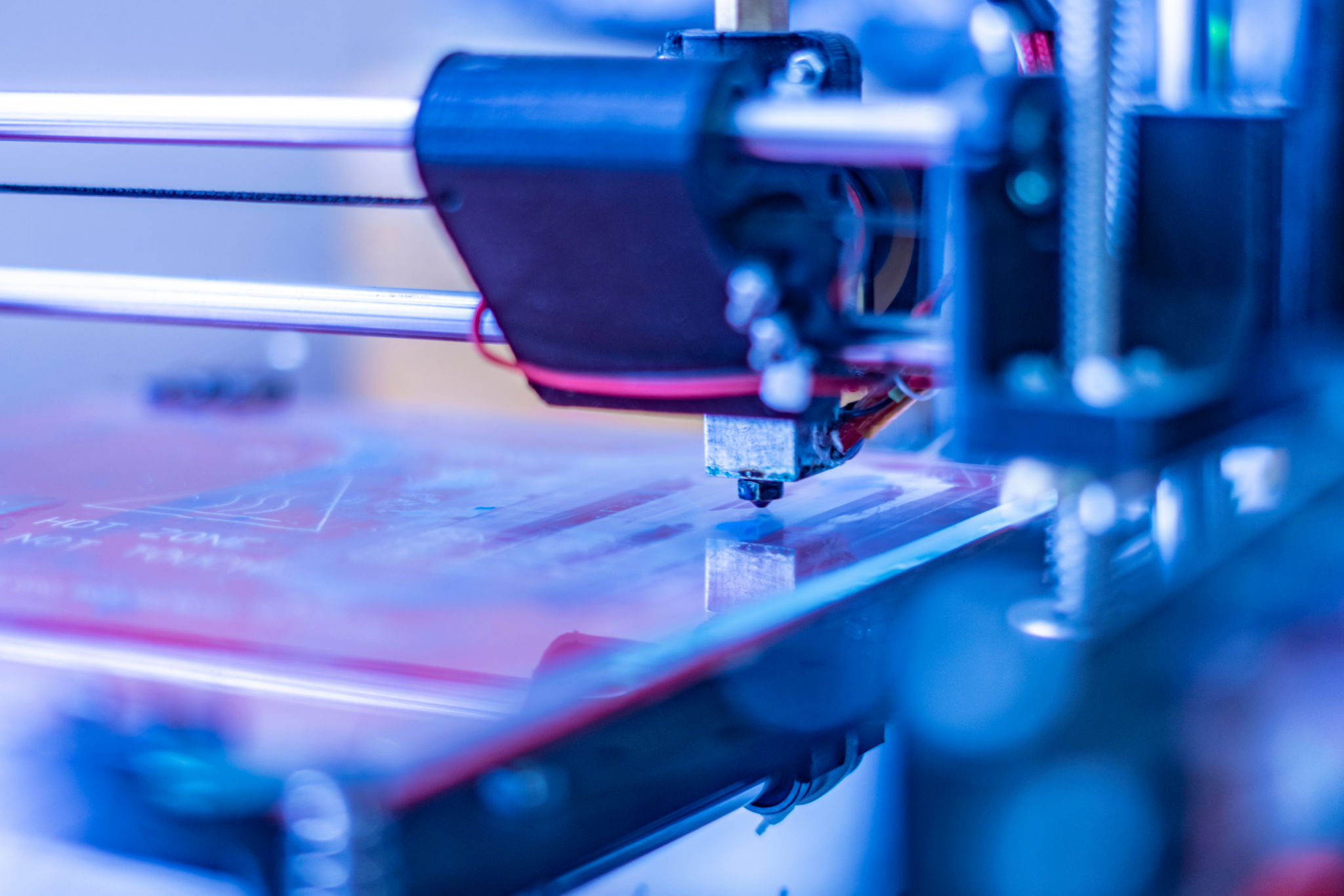

Advancements in 3D Printing

One of the most significant trends in custom mechanical parts design is the increasing use of 3D printing technology. This innovative approach allows for rapid prototyping and the production of complex geometries that would be impossible or costly to achieve with traditional manufacturing methods. The flexibility and speed offered by 3D printing make it an attractive option for designers looking to explore new possibilities.

Materials and Applications

The range of materials available for 3D printing has expanded dramatically, from plastics and metals to ceramics and composites. This diversity enables the creation of parts for a wide array of applications, from aerospace components to medical devices. As material science continues to advance, we can expect even more options to emerge, further broadening the scope of what can be accomplished with 3D printing.

Integration of Artificial Intelligence

Artificial Intelligence (AI) is playing a transformative role in custom mechanical parts design. AI-powered software tools are now capable of optimizing designs for performance, cost, and manufacturing efficiency. By analyzing vast amounts of data, these tools can identify the most effective design solutions, reducing time-to-market and minimizing errors.

Generative Design

Generative design is a cutting-edge technique that leverages AI to create multiple design iterations based on predefined parameters. By inputting constraints such as weight, material, and strength requirements, designers can explore a multitude of potential solutions, selecting the one that best meets their needs. This approach not only streamlines the design process but also fosters innovation by uncovering design possibilities that may not have been considered otherwise.

Enhanced Collaboration with Cloud-Based Tools

The shift toward cloud-based design platforms is another significant trend in the industry. These platforms facilitate seamless collaboration among teams, regardless of their geographical location. By enabling real-time data sharing and communication, cloud-based tools enhance productivity and ensure that all stakeholders are on the same page throughout the design process.

Security and Accessibility

While cloud-based tools offer numerous advantages, they also raise concerns about data security and accessibility. However, advancements in cybersecurity measures are continually being developed to safeguard sensitive information. Additionally, cloud platforms are becoming more user-friendly, making them accessible to designers with varying levels of technical expertise.

Conclusion

The future of custom mechanical parts design is bright, with numerous trends and innovations paving the way for more efficient and creative solutions. As technologies such as 3D printing, artificial intelligence, and cloud-based collaboration continue to evolve, designers will have unprecedented opportunities to push the boundaries of what is possible in mechanical engineering. By staying informed about these developments, professionals in the field can harness these tools to drive innovation and achieve exceptional results in their projects.